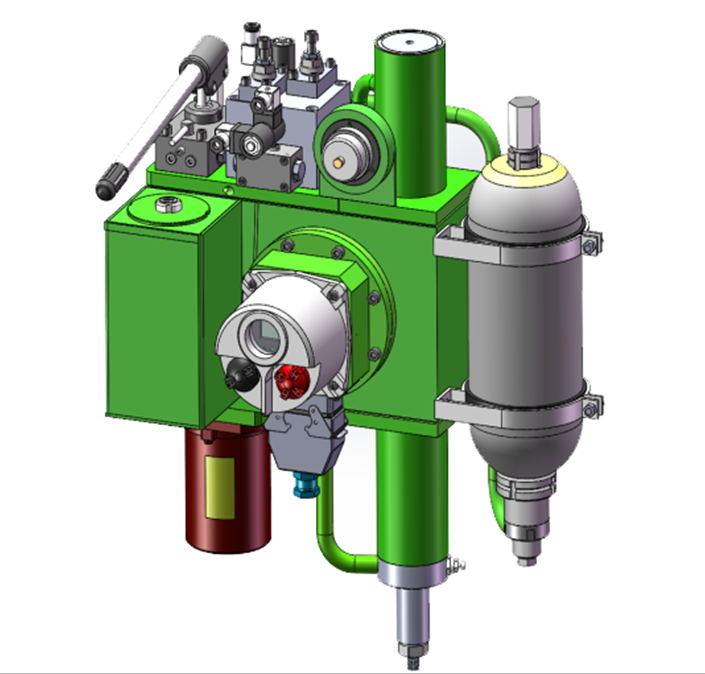

CDG electro-hydraulic actuator has small installation space, without external hydraulic station, oil pipeline, electric control box and cable. It can be installed at any angle on site. It can be used for remote simulation debugging with valve, which can reduce the on-site debugging cost and leave the factory with potential problems. The product technology is leading the domestic industry, widely used in petroleum, chemical industry, metallurgy, electric power, light industry, shipbuilding, building materials City processing and other process pipelines, to implement regulation or fast cut-off control.

According to the transmission mode of the valve, there are 0-90 ° rotary motion and linear motion, which can form two types of actuators: 1. Angular stroke electro-hydraulic actuator (regulating type and switching type); 2. Straight stroke electro-hydraulic actuator (regulating type and switch type).

There are many valve working conditions, which need fault or power failure automatic reset can form two types of actuator: 1. General automatic reset (1 ~ 4 seconds, adjustable and switch type), 2. Quick reset (0.5 seconds, regulating type and switch type)

The hydraulic control check valve is suitable for the pump outlet pipeline with water as the medium. It is used to avoid and reduce the backflow of medium and excessive water hammer in the pipeline system, so as to protect the pipeline system. Its function is to replace two valves with one valve. Under this condition, two types of actuators can be formed: 1. Full hydraulic accumulator type electro-hydraulic actuator (quick closing and then slow closing interlocking type); 2. Semi hydraulic control check valve storage Energy device type (using spring to compress mechanical energy) forms single acting electro-hydraulic actuator (replacing heavy hammer type). |